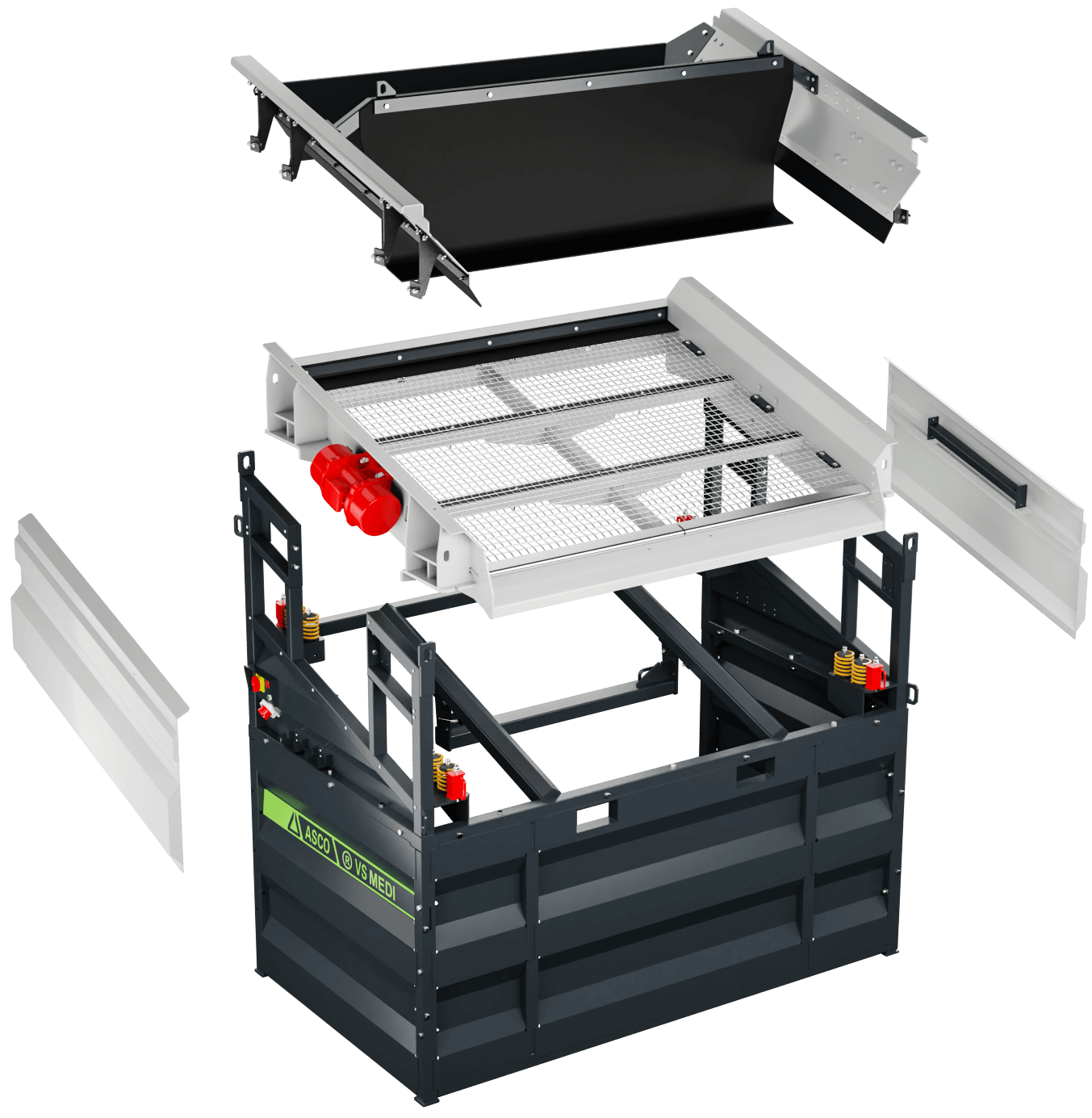

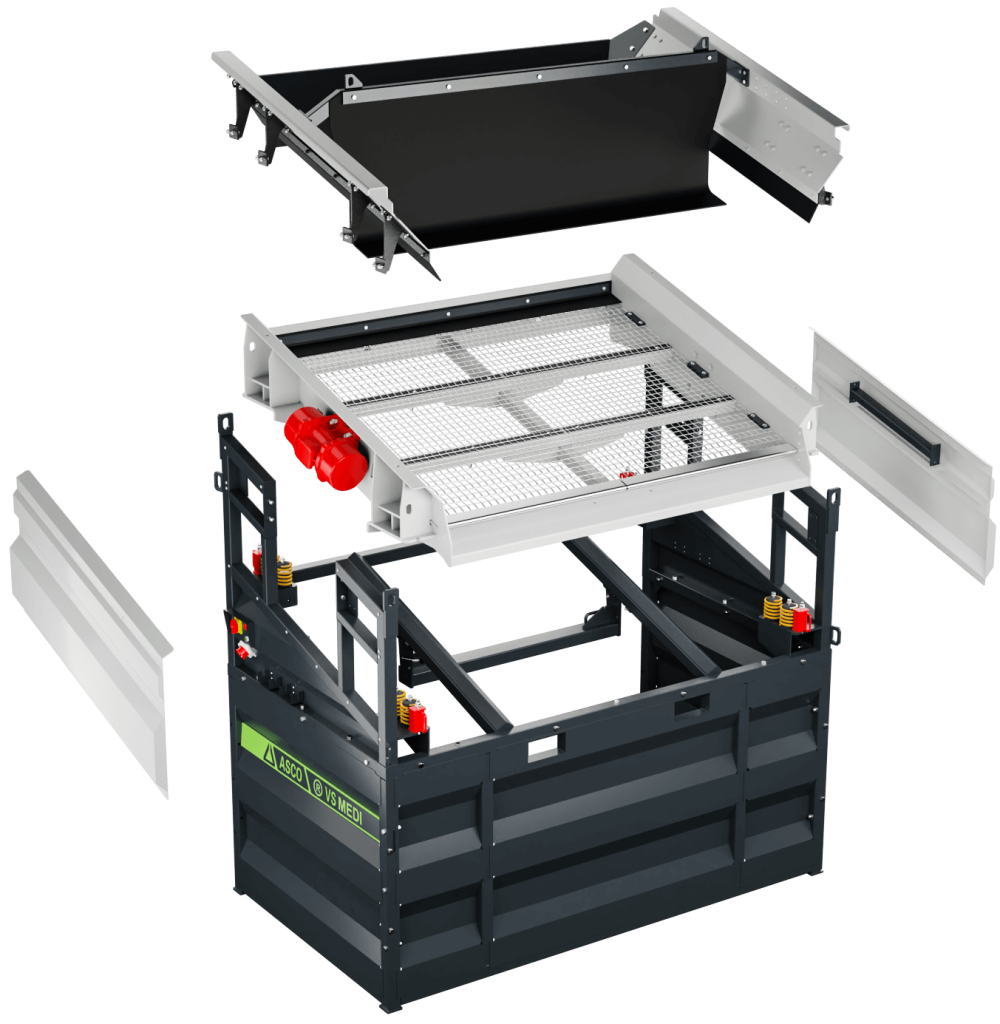

The vibrating screen is mounted on a stable and robust base frame and can be manipulated semi-mobile. The screening process begins with the introduction of the material at the feed hopper of the screen deck. The material is distributed in doses over the vibrating screen deck via an adjustable rubber brake. Depending on the design, the screened material falls in one or two fractions in front of the screen and the fine fraction under the machine.

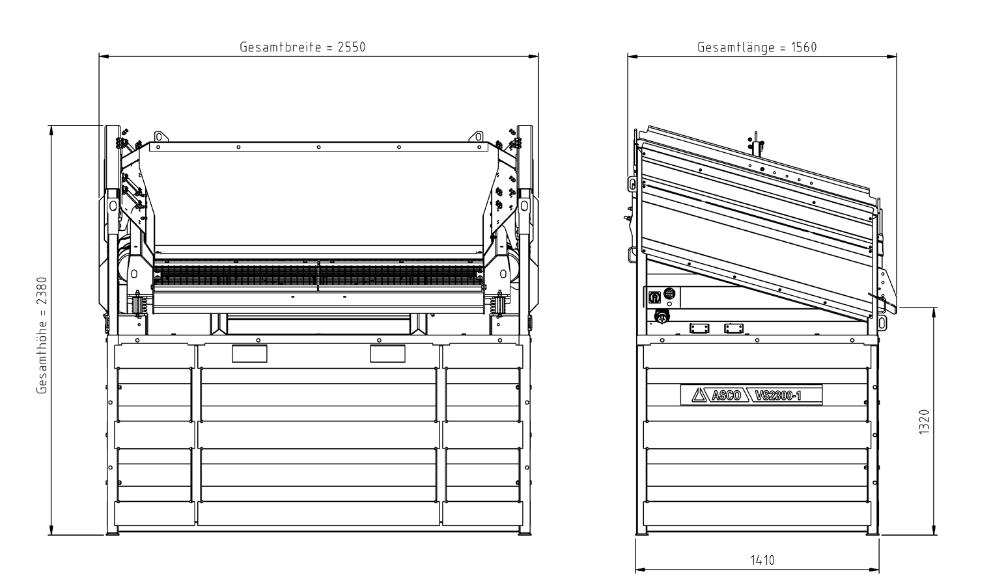

Vibration screen ASCO VS MEDI-1

The compact ASCO VS MEDI-1 vibrating screen offers a robust and powerful base with two vibration motors for a wide range of screening tasks. The machine is particularly convincing for recycling companies and companies in the construction, agricultural and gardening sectors where many different materials have to be processed in narrow time windows.

Due to the modular design, a high degree of flexibility is guaranteed and the readability can be individually adapted, making the ASCO vibrating screen suitable for a wide range of applications and materials.

Available in your company colours!

Seve a variety of materials

Interchangeable screen covers in different thicknesses and perforations

Introduction video VS MEDI

The ASCO flat deck screening plants are the innovation!

Turn your 1-deck screening unit into a 2-deck screening unit very easily.

The exchangeable screening head makes this very easy.

Vibration screen ASCO VS MEDI-2

The vibrating screen is equipped with 2 screen decks, which can be fitted with different screencan be equipped with different sieve linings. The two powerful vibration motors produce an optimal sieving result. The compact ASCO vibrating screen VS Medi 2/2 is easy to operate, manipulable and flexible.

Different screen linings are available with regard to thickness and mesh size

for every application.

The screen linings are easy to change.

- Modular design – can be changed from 1 deck to 2 decks at any time

- Two vibration motors

- Variable adjustable and exchangeable rubber brake

- Reinforced base frame

- Variable placement – can be mounted on our base frame or e.g. on concrete walls